Black Dragon Forge

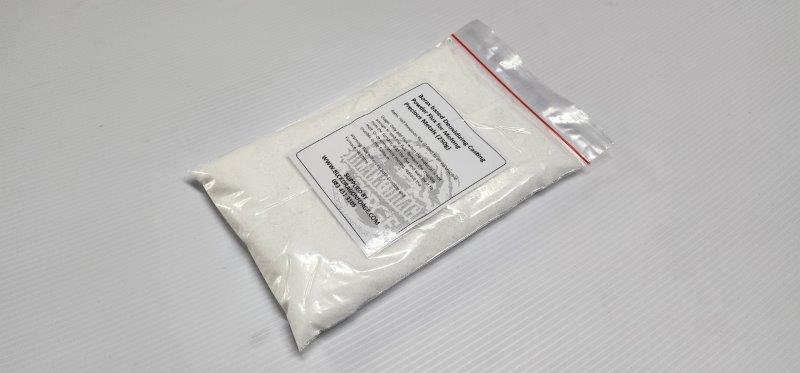

Borax based Deoxidizing Casting Powder Flux (250g)

Borax based Deoxidizing Casting Powder Flux (250g)

9 in stock

Couldn't load pickup availability

SHIPPING / DELIVERY

SHIPPING / DELIVERY

Not applicable to Digital Goods or Class Bookings.

Local Shipping:

- We currently only offer shipping within South Africa using The Courier Guy.

- Shipping is calculated at checkout and is based on your physical delivery address and the weight of the ordered goods.

- We ship within 24 hours from order placement.

- Delivery by The Courier Guy is normally within 3 business days from order collection.

- You will receive an email with your order tracking information as soon as the order is processed.

- All real-time order tracking is done online, via The Courier Guy website.

International Shipping:

- International customers can arrange their own courier services to collect from the Black Dragon Forge Workshop in Lanseria.

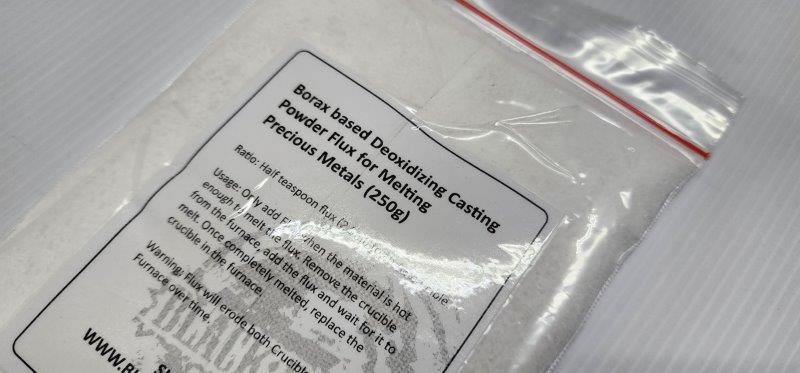

Borax based Deoxidizing Casting Powder Flux for Melting Precious Metals (250g)

Borax based Deoxidizing Casting Powder Flux is used to prevent air oxidation: During melting, Deoxidizing Casting Flux will protect metal from the oxidizing atmosphere of the furnace. Deoxidizing Casting Flux near the bottom of the crucible will melt last and float up to the surface of the molten metal dissolving oxides, silica (sand) and other non-metallic impurities.

This high-grade, Borax based Deoxidizing Casting Flux keeps your metals cleaner during melts and pours. It is also great for seasoning your graphite crucibles, and while melting, casting, and refining metals such as gold, silver, copper, iron, sterling silver, tin, nickel, and their alloys. Add the Flux to your melts to draw gasses and oxides out of molten metal.

Weight: 250 grams

Packaging: Ziplock Bag

Contents: Deoxidizing Casting Powder Flux (Borax based)

Ratio: Half teaspoon flux (2.5ml) to an A6 crucible

Usage: Only add Flux when the material is hot enough to melt the flux. Remove the crucible from the furnace, add the flux and wait for it to melt. Once completely melted, replace the crucible in the furnace.

Warning: Flux will erode both Crucible and Furnace over time.

NOTE: Not suitable for forge welding steel.