Mastering the Art of Thermal Cycling

Neels Van Den BergIf you're a bladesmith, you know that creating a high-quality forged blade requires a meticulous process that involves various thermal cycling techniques. Among these techniques are homogenizing, normalizing, and sub-critical cycling, also known as spheroidize annealing. Each cycle plays a crucial role in shaping the blade's properties and achieving the desired characteristics. In this article, we will focus on the art of normalizing and how it contributes to the mastery of thermal cycling for forged blades.

What is Normalizing and Why is it Important?

Normalizing is a critical step in the thermal cycling process, and it directly follows after forging the blade. The primary objective of normalizing is to create uniform crystal sizes throughout the blade. This uniformity enhances the blade's overall strength, toughness, and performance. By carefully controlling the temperature during normalizing, we can avoid large grain structures, which can lead to weaknesses in the blade.

Step 1: Homogenizing - Achieving Crystal Uniformity

Before diving into normalizing, it's essential to perform the homogenizing step. During homogenization, the entire blade is heated to a temperature slightly higher than its non-magnetic point or critical temperature. To gauge the temperature accurately, look for a nice even dark yellow color in the steel. Employ magnet testing to ensure you've reached the correct temperature. Afterward, let the piece cool down to a black heat, around 550 degrees Celsius, where the steel no longer exhibits any color in the dark.

Step 2: The Art of Normalizing

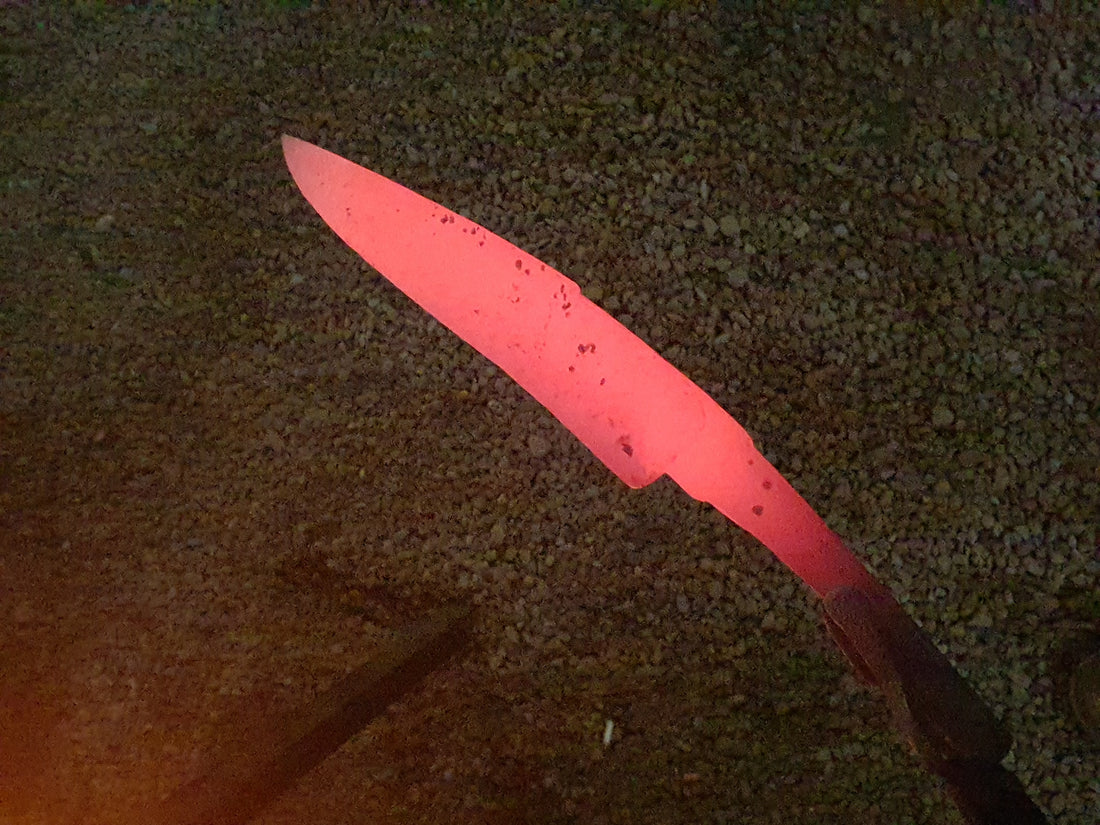

Now comes the crucial step of normalizing. Heat the blade until the steel loses its magnetism and any shadow completely disappears. Performing this process in dim light can be beneficial, as shadows might not be visible in a brightly lit workspace. Again, use magnet testing to confirm the temperature accuracy. Once the correct temperature is achieved, allow the blade to cool down to a black heat, around 550 degrees Celsius, where no color remains visible in the dark.

Step 3: Sub Critical or Spheroidize Annealing

After normalizing, it's time for sub-critical cycling or spheroidize annealing. This step involves heating the blade to a dull red color, but not hot enough for any shadows to appear. The steel should still be magnetic and slightly below the critical temperature. Employ magnet testing to ensure you're at the right temperature. Once done, allow the piece to cool down to room temperature.

The Crucial Importance of Blade Straightness

Throughout the thermal cycling process, it is vital to constantly check the blade for straightness. Stresses can accumulate during heating and cooling, leading to warps or twists in the blade. Address any issues of straightness as soon as they appear.

Magnet Testing: Quick and Effective

Magnet testing is a powerful tool during thermal cycling. Briefly remove the blade from the forge, test it with a quick touch of the magnet, and promptly return it to the fire. Keep the blade within the flames during testing to prevent heat loss and ensure accurate indications from the magnet.

Embrace Patience and Focus

The thermal cycling process demands time and attention. Make yourself comfortable at the forge, and don't rush through the steps. Focus on each stage, keep track of the required temperatures, and maintain a steady hand throughout the process.

Conclusion

Mastering the art of thermal cycling, is essential for crafting high-quality forged blades. By carefully controlling the heating and cooling temperatures, we achieve uniform crystal sizes, resulting in improved blade strength and performance. The combination of homogenizing, normalizing, and sub-critical cycling ensures that the blade reaches its full potential and becomes a reliable tool or work of art.

Frequently Asked Questions (FAQs)

Q1. What is the purpose of normalizing in blade forging?

Normalizing aims to create uniform crystal sizes throughout the blade, enhancing its strength and toughness.

Q2. How do I test the temperature during thermal cycling?

Magnet testing involves using a magnet to check the blade's magnetic properties at different temperatures.

Q3. Can I skip the homogenizing step?

Homogenizing is crucial for achieving crystal uniformity and should not be skipped.

Q4. What causes warps or twists in the blade during thermal cycling?

Stresses can accumulate during heating and cooling, resulting in blade warps or twists.

Q5. How important is blade straightness after the thermal cycling process?

Blade straightness plays a pivotal role in achieving optimal cutting performance and is vital during the subsequent finishing process of knifemaking.